While the regional economy has diversified greatly in recent years, manufacturing remains critical to Greater Peoria. Not only is it the home of Caterpillar, Komatsu and Keystone, nearly 400 manufacturing firms operate in the five-county region that includes Logan, Mason, Peoria, Tazewell and Woodford counties. According to a recent analysis by Thomas P. Miller & Associates, these businesses employed 27,714 workers in 2013, accounting for nearly $6.7 billion, or 32 percent, of the Gross Regional Product.

In conjunction with the Illinois Manufacturing Extension Center at Bradley University, iBi presents a snapshot of 20 of the area’s unique manufacturers. From modular homes and heavy equipment simulators to metal tools and food items, a wide range of products are being manufactured in the heart of the Midwest.

Alcast Company

Peoria, Illinois

Founded in 1970, Alcast is a permanent-mold aluminum foundry, supplier and manufacturer of high-quality aluminum castings, with more than 110,000 square feet of manufacturing space. The castings manufactured by the company include: brake calipers for recreational vehicles and motorcycles; RV and automotive brake master cylinders; torque converters; and components for industrial fans, blowers and impellers. Alcast is an ESOP company, owned and operated by its employees, so all of them have a financial stake in ensuring customer satisfaction. alcastcompany.com

BEER NUTS, Inc.

Bloomington, Illinois

BEER NUTS, Inc. uses the same formula for its products today as it did back in 1937, when Arlo Shirk and his father, Edward G. Shirk, purchased a small confectionery store in downtown Bloomington, and with it, the recipe for a special glazed peanut. While its products began distribution in taverns and pubs across the country, they quickly spread to grocery, convenience and mass stores, and later, its online store.

Today, all of its products continue to be produced at a single 100,000-square-foot facility in Bloomington, under the direction of James A. Shirk and his family, the next generation of Shirks. With the same commitment to freshness and quality, the family is proud that the BEER NUTS trademark brings smiles and instant recognition in all 50 states and several countries around the world. The company’s current product list includes the original BEER NUTS peanuts, as well as almonds, cashews, chocolate-covered peanuts, and a variety of bar and party mixes. beernuts.com

Bella Elevator Peoria, Illinois

Peoria, Illinois

A manufacturer of custom home elevators, wheelchair lifts and light-duty commercial elevators, Bella Elevator has been operating on Galena Road in Peoria for six years. Its products, customized to meet each customer’s unique application, are distributed throughout the U.S. and in some parts of Canada.

As the industry continues to consolidate, Bella Elevator has taken advantage of new opportunities by focusing on customer service above all else. During the recent recession, several competitors faded away, but with its strong commitment to the customer, Bella Elevator continued to thrive. Looking to the future, the company will focus on R&D and employee training, says company president Rick Crane, as well as continued capital investment in an effort to improve efficiencies, both on the shop floor and throughout its office operations.

Boley Tool and Machine Works

East Peoria, Illinois

Since 1963, Boley Tool and Machine Works has consistently met ever-increasing demands for quality, responsiveness and economy in the production of precision machined parts and tooling. At its East Peoria facility, skilled machinists utilize the latest CNC machine tools and sophisticated support equipment to produce a wide range of complex parts for diesel engines, heavy equipment and aerospace applications. Its staff of more than 50 have the expertise to meet the most demanding machining challenges, while its computer system, material control and quality systems enable the company to assure the same responsiveness and quality for any order, whether one piece or thousands. boleytool.com

The Burt Coyote Company

Yates City, Illinois

The Burt Coyote Company specializes in the creation of Lumenoks—lighted arrow nocks used for shot placement recognition and arrow retrieval in hunting and fishing. It got its start in 1998 when Curtis Price, company president, was out bowhunting. After missing a buck that came within range, he conceived of an illuminated nock (the notch at the rear of the arrow) that would allow him to see the arrow in flight and mark its location if it missed its target. After four years of experimentation and 17 prototypes, Curtis and his brother, Eric Price, filed a patent in 2002 and began production.

The Lumenok uses the arrow shaft to connect a battery to a bright LED light, visible under all conditions. When released, the nock is driven forward, completing the circuit and lighting the light, allowing shooters to confirm a hit or miss instantly. Lumenoks are available to fit more than 90 percent of arrow shafts on the market; they are also available for crossbows. In addition, Burt Coyote supplies crossbow bolts and full-length arrows with factory-installed Lumenoks, as well as fishing arrows with lighted nocks, ideal for bowfishing at night. lumenok.com

CountyLine Tool

East Peoria, Illinois

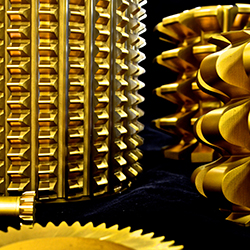

For more than three decades, CountyLine Tool has focused on putting quality first. Specializing in the manufacturing and refurbishment of industrial cutting tools, the company’s “fanatical devotion to quality” was recognized in 2013 by a top-tier, global provider of custom tooling when it became the first KOMET SERVICE partner in North America.

To keep up with evolving technology, CountyLine Tool has focused its efforts on capital investment, including the recent purchase of a top-of-the-line CMM (coordinate measuring machine) and a new Anca MX-7—a powerful CNC grinding machine—with a pallet loader designed to run large lot sizes. These investments help keep costs reasonable, provide unsurpassed quality, and offer additional abilities to match new tool geometries.

In the near-future, owner Vonda Jones plans to complete ISO certification status and apply for Woman Owned Small Business certification. Meanwhile, the company continues to focus on building relationships, old and new, and expanding its market share. countyline-tool.com

Evonik Industries

Mapleton, Illinois

One of the world’s leading specialty chemical companies, Evonik makes products for its Household Care, Interface & Performance and Personal Care business lines at the Mapleton site. Its active ingredients can be found in many consumer products, including fabric softeners, hair care and skin care products, as well as industrial products used in the construction, mining, oil drilling, lubricants and agriculture markets. The plant has been in continuous operation since January 1963, when it was owned by Archer Daniels Midland Company. Over the next three decades, the site was owned by Ashland Inc., Sherex Fastening Solutions and Witco Corporation, before being acquired by Goldschmidt SKW, now Evonik Corporation, in 1999.

The company cites an increased focus on sustainability as the biggest change in its industry in recent years, and remains focused on safety, with increased safety-related communication among staff, additional plant visibility and expanded equipment inspections. The company also cites a continued investment in innovation, with 2,300 of its 33,000 worldwide employees working in research and development at 35 locations around the world. evonik.com

Excalibur Seasoning Company

Pekin, Illinois

Founded in 1986, Excalibur produces seasoning formulas for the meat processing industry, offering an extensive line of seasoning blends and sauces sold in retail outlets throughout the country. Its customers include national and international meat processors, food manufacturers, food service operators and retail grocery chains.

With more than 50 years of experience in the meat industry, Jerry Hall owns Excalibur with his wife Vinetta, while 19-year employee Tom Hornstein serves as CEO. The company’s staff combines expertise in both the processing and retail sides of the food industry, and prides itself on problem solving, product marketing and availability to its customers.

New food safety and quality control demands require Excalibur to carry a Global Food Safety Certification. Recently audited by Silliker Labs for the Australia-based Safe Quality Food Institute, the company was awarded SQF Level 3 certification—among the highest levels of achievement in international food safety. Future plans include working toward another expansion of its current facility to service additional markets and increase capacity through further automation. excaliburseasoning.com

The Greenbrier Companies

Peoria, Illinois

In business for nearly 60 years, the Greenbrier Companies is a leading supplier of transportation equipment and services to the railroad and marine industries. Headquartered in Lake Oswego, Oregon, Greenbrier builds new railroad freight cars at four manufacturing facilities in the U.S. and Mexico, and marine barges at its Portland, Oregon deep-water site. At the Peoria Castings location, the company manufactures and refurbishes railcar components such as draft gears, side frames, bolsters, coupler bodies, fully-assembled couplers, knuckles and more—all vital parts in supporting and connecting the railcars that move freight and passengers across the continent.

The casting and reconditioning service in Peoria is unique because it is well connected to several Class I railroad lines to distribute finished products. The facility can accommodate made-to-order parts and maintains inventory on-site to fulfill immediate requests for its customers, which include the TTX Company, Union Pacific, Canadian National Railway, Canadian Pacific Railway, Burlington Northern and Santa Fe Railway, Union Tank Car Company and the GATX Tank Car Company.

As a result of the domestic energy renaissance brought about by refined fracturing technologies, Greenbrier has expanded production and further diversified its product lines to better serve the energy industry. Having purchased a minority stake in a Brazilian railcar manufacturer, it plans to pursue growth opportunities in Latin America. Recent product innovations include a new “Tank Car of the Future,” which is eight times safer than existing legacy tank cars for the movement of crude oil. Robust demand for new railcars will keep the Peoria location busy for many years to come. gbrx.com

Homeway Homes

Deer Creek, Illinois

Homeway Homes specializes in custom-built, energy-efficient modular homes designed around the needs and lifestyle requirements of its customers, managing every aspect of the building process from start to finish. The company offers more than 60 floor-plan options—including its exclusive Women-Centric designs—all of which can be customized. The homes are built using state-of-the-art processes and equipment, as well as trusted brands by Merillat, Andersen, Moen, Mohawk and Panasonic, and because they are built indoors, construction is not affected by the weather. Homeway Homes has three model home centers—in Goodfield, Spingfield and Galesburg—where potential customers can review floorplans and home amenities, while its construction facility in Deer Creek offers guided tours every Saturday at 1pm. homewayhomes.com

IVP Plastics

Washington, Illinois

IVP Plastics is a full-service thermoplastics expert—designing, molding, machining, finishing and assembling complex components for a diverse portfolio of customers. Since its founding in 1953 with four machines in Peoria, it has grown to a 54,000-square-foot operation with 18 machines and 11 engineers on staff. The company also recently acquired an additional facility in St. Louis.

IVP’s certifications, quality and delivery performance have earned it substantial growth in the automotive, off-road, construction, food, sports and medical industries. Its proprietary line of polymer reducing bushings—for use in the electrical, water and natural gas industries—has been around since 1976. The company provides design assistance through its in-house engineering staff and has developed a standardized process to help customers convert parts from metal to plastic, reducing environmental issues and costs related to weight, painting and plating.

“Diversifying our customer base has been both an opportunity and a challenge,” adds Daryl Lindemann, company president. “With the downturn in the economy starting in 2008, we realized it was in IVP’s best interest to diversify into different end markets to mitigate the effects of cyclicality and seasonality… This strategic effort has taken [us] several years to execute.” The result is a company better able to weather the ups and downs of the business cycle. Future plans include larger press sizes—potentially up to 3,000 tons—to satisfy customer demand for larger parts. ivpplastics.com

J.K. Williams Distilling

East Peoria, Illinois

This family-owned distillery has produced locally handcrafted whiskey and bourbon since opening in September 2013. Named after the founders’ great-great grandfather, a Prohibition-era bootlegger, the Williams family is carrying his recipes from the 1920s into the 21st century. J.K.’s Young Buck Bourbon, named after J.K.’s son Buck, is testament to how a century-old family recipe meets modern distilling techniques to create a smooth, full-bodied bourbon. It’s aged a minimum of two years in a specially-designed, patented honeycomb barrel, which speeds up the aging process, yet retains the smoothness and quality of other craft bourbons.

J.K.’s Young Buck Bourbon, along with J.K’s Original Corn Whiskey, Smitty’s Apple Pie and a number of fruit-based whiskeys, is sold out of the company’s East Peoria tasting room and at numerous local retailers and specialty retailers throughout Illinois. Beginning this year, its product will also be available in Wisconsin. As the company continues to expand its distribution network, it plans to introduce a number of new bourbons and whiskeys in 2015. jkwilliamsdistilling.com

Langston Bag of Peoria

Peoria, Illinois

A wholly owned subsidiary of the Langston Companies, Langston Bag of Peoria manufactures a variety of multiwall bags and offers resources for nearly every aspect of one’s packaging needs. The Peoria location carries all sizes of multiwall, textile and bulk bags—which can hold from 40 pounds of feed to two tons of sand—as well as printed stock bags and a complete line of high-strength, knotless industrial sewing thread. Its capabilities include up to six plies, including specialty plies for moisture and grease protection, and the bags can be custom-printed with any logo or design. Langston’s in-house art department guides customers through the design process to create high-impact packaging, as well as assisting in other areas, such as bar coding and regulatory requirements. langstonbagofpeoria.com

Midwestern Wood Products Co.

Morton, Illinois

In 1968, Jerry Young, a sales representative for mouldings and other building materials, decided to get into manufacturing. Nearly half a century later, Midwestern Wood Products Co. remains family-owned, designing and manufacturing high-quality interior millwork, utilizing mainly American hardwoods. Young’s patented WOODGRID Suspended Coffered Ceiling System has been featured in numerous magazines and twice on the Hometime TV show. Both elegant and affordable, it’s versatile for all applications—whether new construction or remodel, residential or commercial—and can be optimized for any space, giving each ceiling a custom, well-planned look. The company also manufactures a complete line of architectural millwork, custom trim, wainscoting and wall systems, carvings and other wood products out of domestic hardwoods. woodgridcofferedceilings.com

Oak State Products

Wenona, Illinois

Since 1956, Oak State Products has been known for its quality baked goods and innovative approach to contract baking, from the pre-oven to post-oven to packaging phases. Over the years, the company has grown to 300 employees, transitioning from producing Archway cookies to running around-the-clock production for a wide range of customers. Its fully-equipped R&D lab works seamlessly with customers to develop competitive and highly marketable baked goods.

The company’s products include the Shelf Life Extender, a gel developed in-house which extends the life of baked goods, and numerous specially-formulated cookie crumbs and inclusions, ranging in flavor, texture and size. This includes more than 30 chocolate formulas, fruit flavors and shortcake varieties, graham, oatmeal and oatmeal raisin, granola, pie crust, streusel, vanilla, ancient grains and custom formulations. Oak State’s modern bakery encompasses 200,000 square feet of state-of-the-art equipment, capable of producing up to 80 million pounds a year, and its chocolate enrobing line is one of the largest in the country. oakstate.com

Parker Fabrication

Morton, Illinois

For more than 25 years, Parker Fabrication has produced high-quality components and fabricated assemblies for customers ranging from Fortune 100 international OEM manufacturers to local consumers. Its services include welded fabrication, bending, machining and forming, and its products—sold online and company-to-company, both domestic and foreign—include exhaust rain caps for diesel and natural gas engines; tubing elbows for intake, exhaust and cooling applications; and expansion joints for engine exhaust applications, among many others.

Owner Matt Parker touts the company’s short turnaround time and expertise in the production of difficult prototypes, while naming its employees as the company’s strongest asset: “the key to its success.” Over the years, technology and efficiency improvements have allowed the company to grow in size and diversity. In fact, recent growth has led to the need for a facility expansion, currently slated for the first quarter of 2016. parkerfabrication.com

Philippi-Hagenbuch, Inc.

Peoria, Illinois

Founded in 1969 by L.B. Philippi and LeRoy Hagenbuch, Philippi-Hagenbuch, Inc. (PHIL) engineers and builds equipment to customize off-highway haul trucks ranging from 20 to 400 tons in payload. Since its first product, the Autogate Tailgate, introduced the first commercially available tailgate to the aggregates/quarry industry, more than 120 patents have been awarded to LeRoy Hagenbuch or PHIL, with multiple patents currently pending.

Philippi-Hagenbuch offers more than a dozen primary products and many sub-products, which vary by industry, region, and make and model of the haul truck. From sideboards, load ejectors and water tanks to truck-mounted scissor lifts and vehicle recovery systems, “every PHIL product features two key components—simplicity and efficiency,” says Josh Swank, vice president of sales and marketing. “Simple doesn’t break down easily, and it’s easy and inexpensive to maintain. And all PHIL products need to increase efficiency for our customers… through added payload, reduced fuel consumption and decreased maintenance.”

PHIL products are sold through its internal sales department as well as an extensive network of off-highway truck dealers around the globe. The company is happily rooted in Peoria, but continues to expand through a network of licensees in key international locations, including Australia, Sweden and the Netherlands. philsystems.com

Premier Fabrication

Congerville, Illinois

Since 1973, Premier Fabrication has provided steel fabrication, manufacturing solutions and structural steel services throughout the Midwest, both for its own brands and for private-label owners and OEMs. Among its branded products are barge spouts, which are part of bulk material delivery systems for river terminals and rail unloading facilities. This solution offers a telescoping and slewing trunk section that allows 180 degrees of travel up and downriver, reducing loading times by requiring fewer barge movements. The cornerstone of Premier’s systems is the Premier Spout, designed by its own John Wilham, who has a lifetime of experience in the inland marine and material transportation industries. The Easi-Load Seed Trailer, produced for one of Premier’s exclusive branded customers, delivers seed to the field for safe loading into any planter. Premier manufactures seed trailers in several frame sizes, which can be purchased through Clarks Ag Supply affiliates across the eastern and central United States.

“Global interdependence and competition—and the explosion of information and innovation—have accelerated economic cycles and opened new opportunities for traditional steel fabrication and machine companies,” declares Scott Aberle, majority owner and CEO. “In order to thrive in a global marketplace, Premier has invested in its employees, processes/systems, and a business approach to build long-term relationships with customers.” Future plans include continued investment in its facilities, capabilities and people. In addition, the company is on a multi-year development plan of complementary products to support its line of barge spouts. premierfabrication.com

Shamrock Plastics

Peoria, Illinois

Founded in 1968, Shamrock Plastics, Inc. started as a supplier of custom vacuum-formed plastic parts and has since expanded to include pressure-forming—an economical alternative to the more traditional injection molding technique—for the off-road, building, food and environmental industries. The company has also developed its own line of yard lamp decorations, called “Lamplighters by Shamrock.”

Led by owner and CEO Mary Cay Westphal, Shamrock has been a woman-owned company since 1986. It is ISO 2008-certified and has been certified by Caterpillar for 23 years, with the last two years being platinum-certified, a distinction attained by just 65 Cat suppliers worldwide. New technology keeps the company competitive as it continues to evaluate the need for upgraded equipment to keep up with the improvements in machinery that arise from year to year. shamrockplastics.net

Simformotion

Peoria, Illinois

In 2008, Caterpillar Inc. decided to license its simulator business to an outside company; the following year, it awarded the license to CSE Software, founded in 1990 by Ken Pflederer. Simformotion LLC was established thereafter as a separate company to handle the design, manufacturing and sales of simulators. Its dedicated personnel include engineers, project managers, warehouse and sales and marketing staff, while CSE’s team of 3D modelers, physics engineers and programmers develop the simulation software.

Cat Simulators are used to train heavy equipment operators worldwide. Cat engineering specifications are used to model the simulated machine to exacting standards, while actual Cat controls are used on the hardware. To date, more than 100 interactive training exercises have been developed for Cat Simulators. There are 13 machine models available, with more in development.

Simformotion partners with other local manufacturers to build the simulators: Parker Fabrication bends the steel to make the frames, Parsons Company paints them, and Shamrock Plastics forms the pods that hold the controls. After being assembled and tested in Simformotion’s large warehouse in East Peoria, they are then shipped to locations around the world, from Canada and Latin America to Mongolia and China. simformotion.com iBi